Do you know the process behind our Australian made garments 🤔

You're bound to be curious about the journey of our beautiful Australian made garments before they arrive at your doorstep, neatly folded in a parcel. 📦 Let's dive into that process!

Designing and Ideation

Every new style starts with a little spark💡Inspiration usually comes from 2 sources-

1. We get several requests from customers for the same style or feature. This is how we came upon last summer's best sellers, our yoga shorts and bike shorts. So glad we ran with that idea 😉

OR

2. We need (by we, it is usually me 🤣) a style to suit ourselves. The original embroidered wrap dress was mine and this style has now been sold all around the world. This dress is still one of my favourite garments to wear out for dinner. Our 3/4 sleeve t-shirt is "mine" too. I much prefer to wear 3/4 sleeves than long!

Our tunic styles were a combination of both of these sources. Customers asked for these and this is also a style I love to wear 🥰. Yep, I'm living in my short sleeve tunics and bike shorts lately- perfect weather for them 😉. Favourite colour combination - oatmeal marle bike shorts with black short sleeve tunic. Smart enough to wear out in public with a pair of sandals but super comfortable to work in.

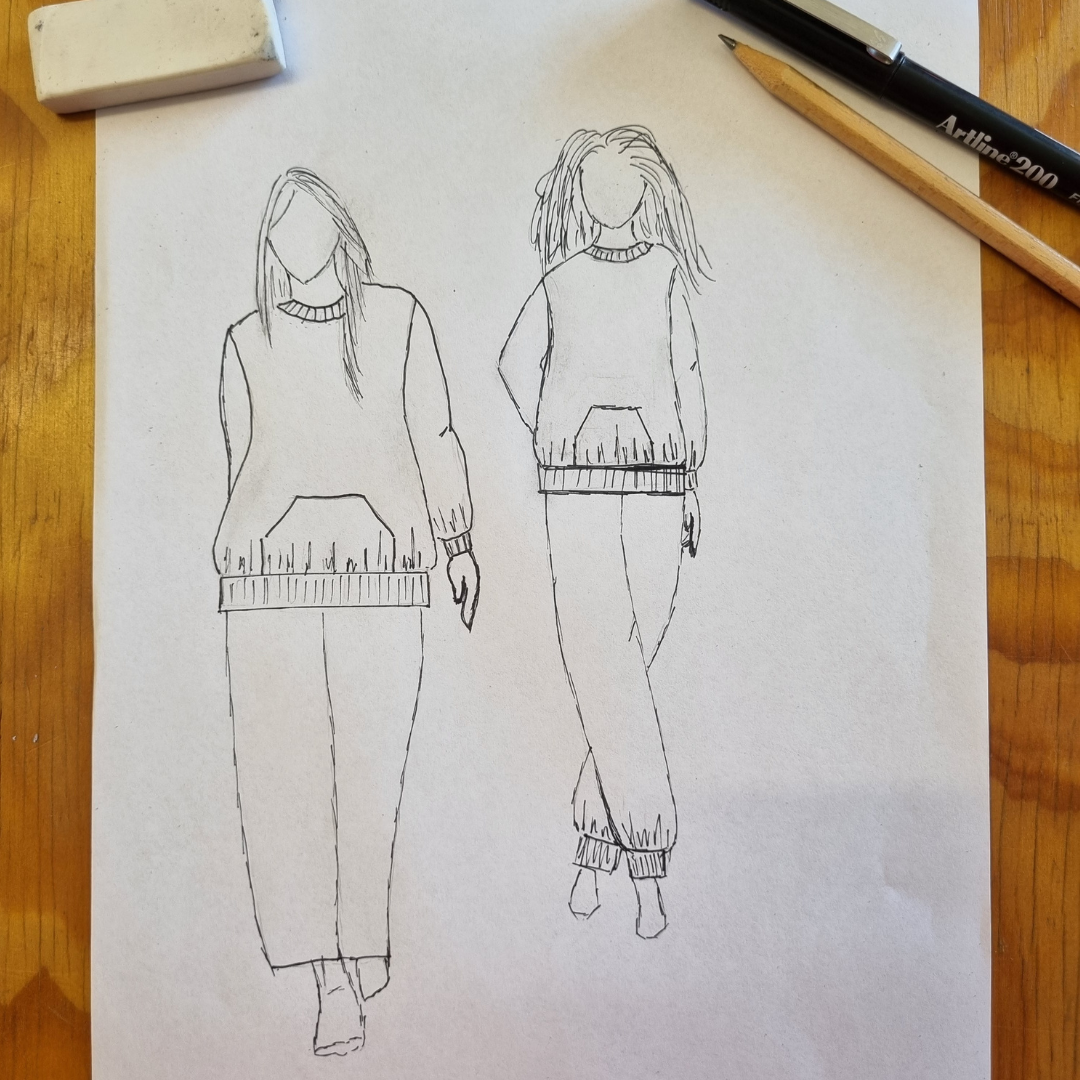

Having settled on a design for our newest Australian made garment, we draw a trade sketch. See above pic of our new sweatshirt, shown with our fleecy pants. This process helps decide if the style will suit both small and plus size women. It also helps decide design features like the length of the garment, sleeves etc before we go and waste fabric (and time). A pencil line is a lot easier to rectify!

Patternmaking and Sampling

Most of our styles are based on a base pattern (called a block) such as a top, pants or skirt block. And some patterns like our leggings and undies are made using precise mathematical equations. This is why they fit soooo good! In the example of our leggings, points A- E= depth of crotch and point H=1/2 F-G measurement🤓

We actively sample each new style, wearing and washing them multiple times to confirm the perfect fit. Is it long enough? Does it sit right? For instance, our range of tunics underwent several iterations- I was determined to position the splits just right, ensuring ample movement without being strained or ripped. We've all had one of those tops😉

In the example of our new sweatshirt shown above, we are using the pattern already used for our fleecy hoodie and just changing the neckline into a ribbed crew neck.

When we've nailed the final sample, we grade the paper pattern up and down in our size range of 8-24 (sometimes 26). That is, a pattern is created for every size and transferred onto cardboard.

Manufacturing

We then do my favourite stage- cutting and sewing 🎈🥳💃. We cut the fabric using one of our four cutting machines. Which machine depends on the quantity of fabric layers and we always use a chain mesh glove. Think butcher's glove or a knight's yoke!

Most garments use 4 different industrial sewing machines to complete a whole garment. That is a total of 11 cones of thread, which as a side note, takes us 8 minutes to set up and thread! This is why we batch sewing most styles in colours, so we are not continually threading machines 😉

And all of this does not include the calculating of production costs for the new style, the photography and uploading to our website, the invoicing/shipping after sales and the social media used to promote these items!

After listing our proceedures of all our Australian made garments, I have just worked out why I am chronically tired! I'm off for a Nana nap..........zzzzzzzz

Jocelyn

Leave a comment